5mm - 50.5" Wide (80' to 110' long) Solexx Greenhouse Covering Rolls - Strong, Flexible, and Insulated Plastic Sheeting for Custom Greenhouses

5mm - 50.5" Wide (80' to 110' long) Solexx Greenhouse Covering Rolls - Strong, Flexible, and Insulated Plastic Sheeting for Custom Greenhouses

Solexx 5mm Rolls make Custom Greenhouse Projects Seamless!

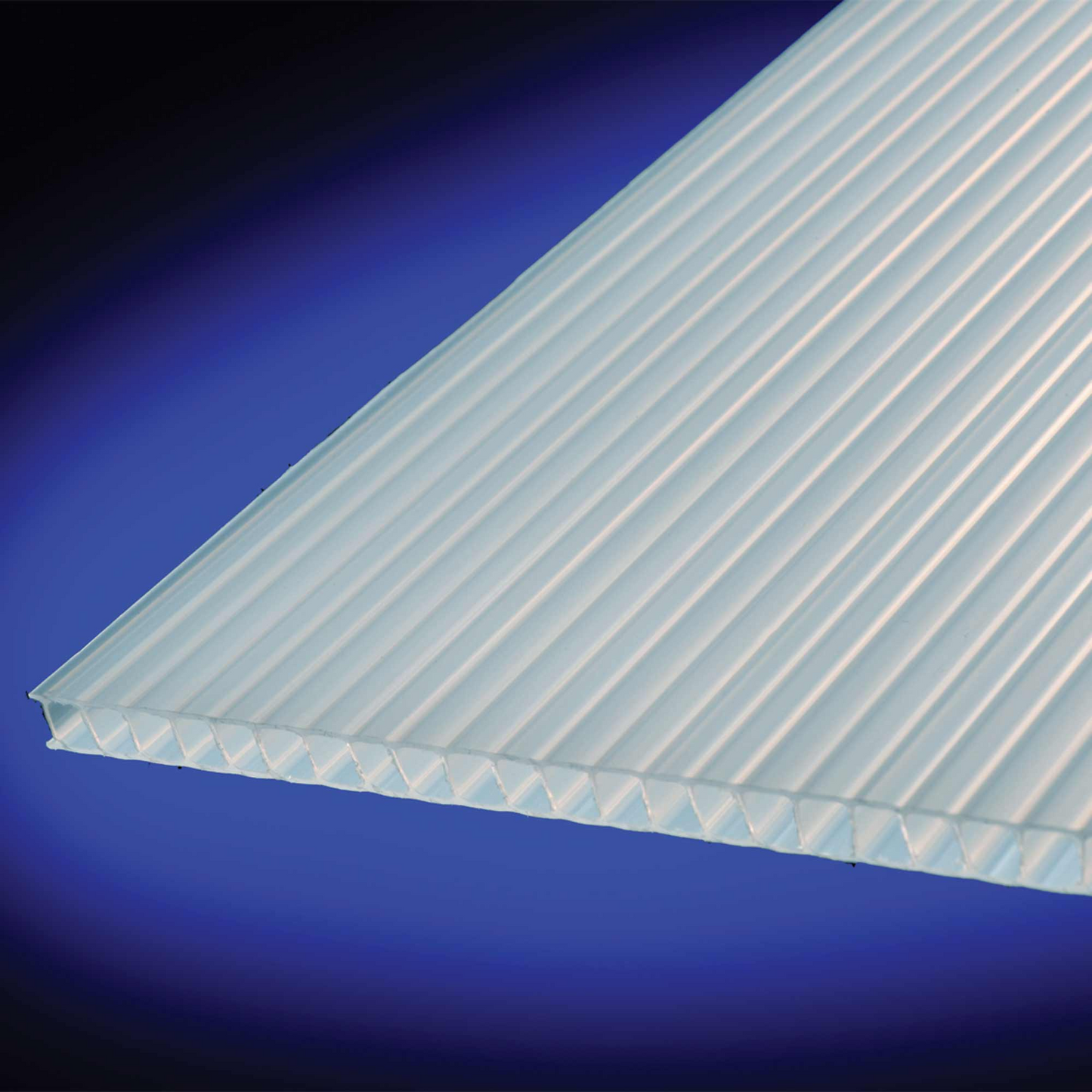

Heavy-duty 5mm Solexx is resilient in strong winds, heavy snow and unfavorable weather conditions season after season - protecting your delicate plants from damage. Mold and mildew will not grow on the plastic's smooth surface so, years later, your greenhouse will look like it did when you first built it. The insulated greenhouse covering, let's you garden all year in most climates.

Solexx Rolls are 50.5" wide and come as long as 110' (shipped UPS). Cut the continuous twin-wall covering to the precise length you need for fewer seams and to eliminate waste. The flutes run the length of the material for superior strength.

Choose 3.5mm thickness for maximum light transmission or 5mm if you live in an area with heavy snow fall or high altitude.

Watch out for imitations, always check the warranty period. Use only UV certified panels!

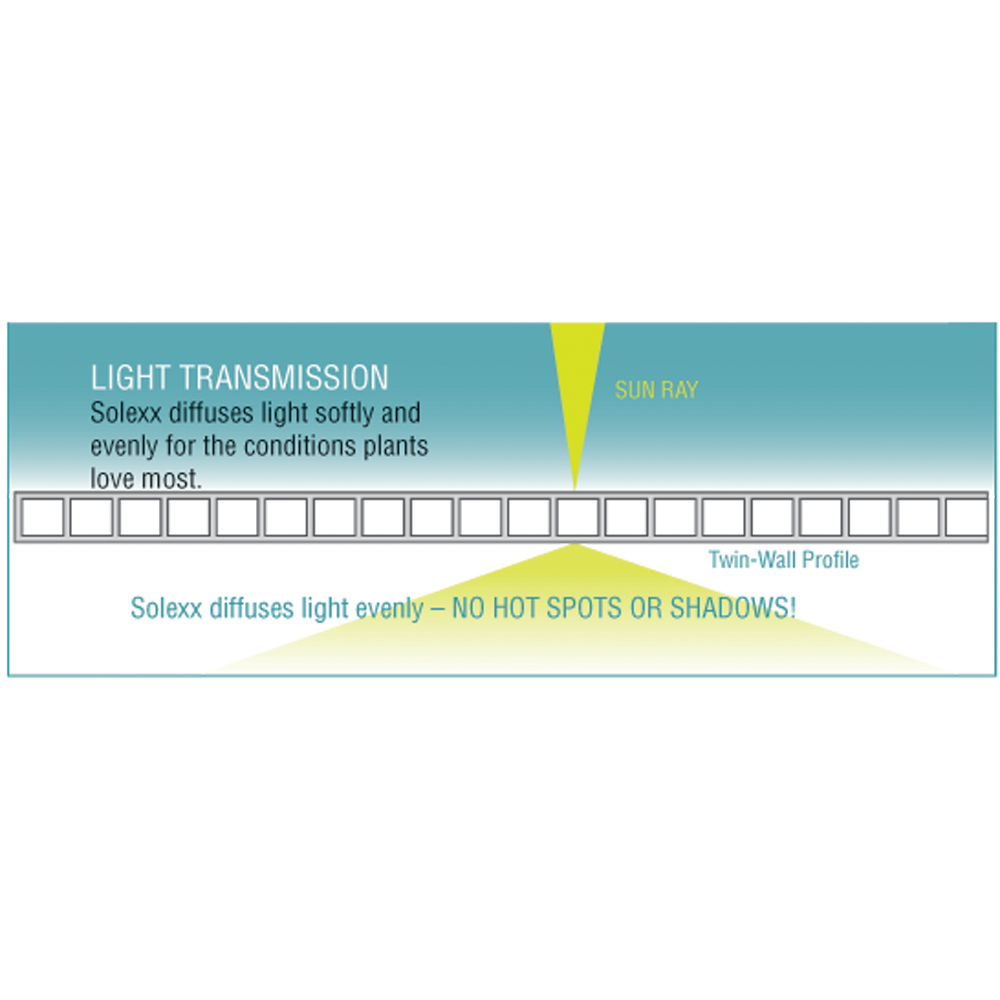

- Diffuses the light, so there are no shadows or hot spots

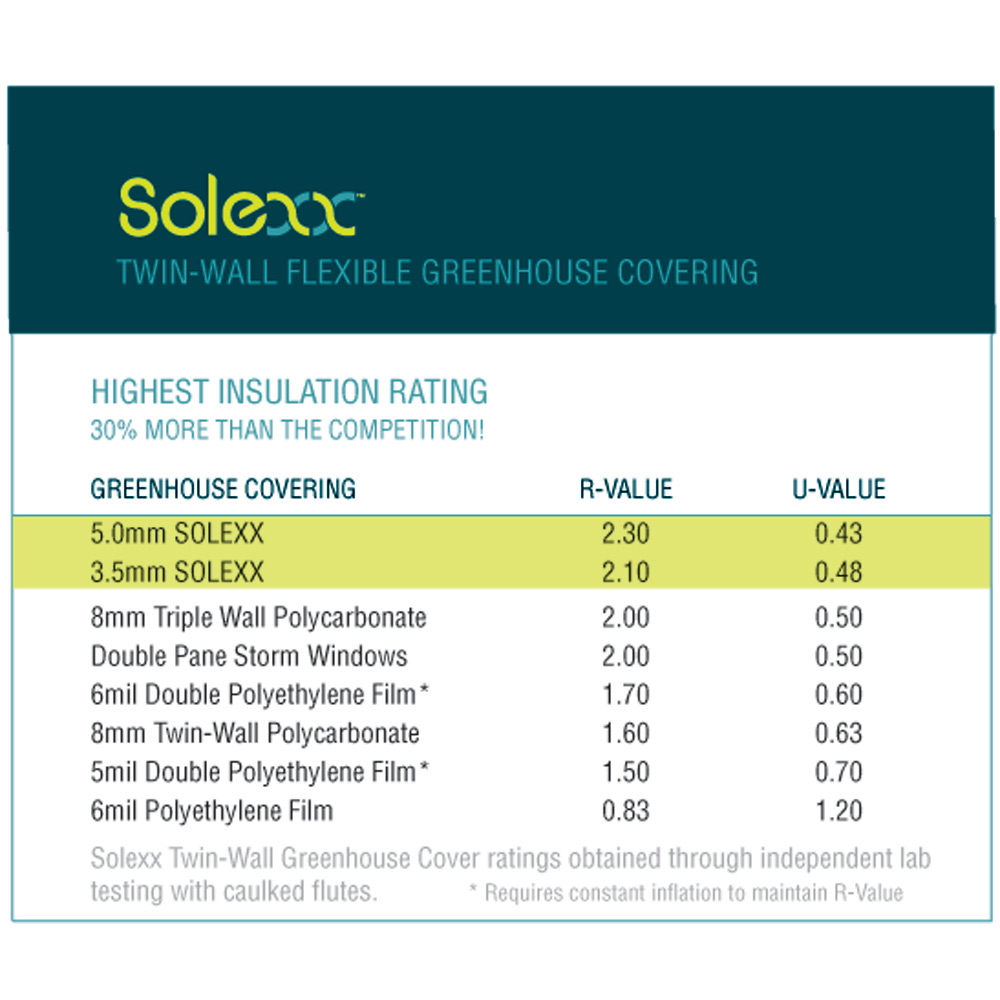

- Insulated to hold in heat

- Extremely strong in wind and snow to protect your precious plants

- Won't scratch or turn yellow with age

- Flexible material bends around tight curves

- Super easy to install

- 10-year limited UV warranty

Special fixed shipping rate of $369.01 for up to 110 feet

Addt'l shipping charges outside contiguous 48 states

DETAILS:

Strong in wind and snow

Strong and shatter-proof, double-walled Solexx protects your seedlings and plants from strong wind, hail, heavy snow, and other harsh weather conditions season after season.

Won't Scratch

Unique Solexx paneling will not yellow, scratch, or tear. Mold and mildew will not grow on the plastic's smooth surface, so years later your greenhouse will look like it did when you first built it.

Diffused Light

Strong double-walled Solexx panel construction scatters available light creating even, bright light inside your greenhouse. University testing proves diffused light accelerates growth and prevents burning in plants!

Insulated

Solexx maintains the temperature in your greenhouse so your plants have as little stress as possible. It holds in more heat then all the other greenhouse coverings, see R-Value Comparison Chart

Easy to Install

Solexx is flexible and can be cut, rounded, or scored to fit perfectly to your structure.

Custom Lengths

Easily cover any structure. With Solexx continuous rolls, you buy just what you need with a minimal amount of seams. Fewer seams provide better insulation and less work!

Hints for Solexx greenhouse glazing application

Solexx greenhouse covering is very strong yet flexible making it easy to work with. Because it is semi-transparent and diffuses light, it makes an ideal covering for greenhouses, end walls, light panels in barns... the possibilities are endless. The following contains a few tips on how to handle this revolutionary greenhouse paneling:

1. Frame Spacing: We recommend that the framing or trusses that will support your corrugated greenhouse panels be placed 16"- 24" apart on center in order to provide maximum support.

2. Flute Direction: Solexx paneling can be attached with the flutes running in either direction on your structure. We've found placing your greenhouse panels so that the flutes run perpendicular to your frame provides the maximum amount of strength for your structure. When attaching the screws to plastic framing or wood, we recommend using our 1" screws with neoprene washers, which helps prevent water from leaking into the flutes of the greenhouse panels. Our ¾" self-drilling screws are for installing the greenhouse panels into a metal greenhouse frame. We suggest placing the screws about 18" apart on the stringers and about 9" apart on the perimeter or any overlapped joint. Be careful not to over-torque the screws, or you may crush the greenhouse panel. The washers should just make a dimple in the greenhouse plastic.

3. Cutting the Greenhouse Panels: The panel is easily cut using a sharp thin utility knife or saw. It is helpful to attach the panel to your structure first, then use a sharp thin utility knife to follow the frame as a cutting guide. It works well to cut the panel with two passes of the knife. The 1st pass is with light pressure to score the panel and set the path the knife will follow for the 2nd pass. The 2nd pass would be done with more pressure to cut through the panel, while making sure the knife is following the score line of the 1st pass.

4.  Using U-Trim: On all 49.5" ends of paneling where there are exposed flutes, you need to insert a ¼" bead of IS800 "clear" Silicone Rubber Adhesive Sealant (caulking) into the flutes, to prevent water intrusion and to bring the paneling to it's maximum insulation factor by trapping air in the middle of the panel. Next, slide a U-trim over the end of the panel for a permanent cap. Secure U-trim with small phillips screws by poking a small starter hole in one side of the U-trim with an ice pick or small nail and screwing through one side of the U-trim and into the Solexx™ paneling. Place each screw approximately one foot apart. Put caulking in all the holes you created to stop water penetration.

Using U-Trim: On all 49.5" ends of paneling where there are exposed flutes, you need to insert a ¼" bead of IS800 "clear" Silicone Rubber Adhesive Sealant (caulking) into the flutes, to prevent water intrusion and to bring the paneling to it's maximum insulation factor by trapping air in the middle of the panel. Next, slide a U-trim over the end of the panel for a permanent cap. Secure U-trim with small phillips screws by poking a small starter hole in one side of the U-trim with an ice pick or small nail and screwing through one side of the U-trim and into the Solexx™ paneling. Place each screw approximately one foot apart. Put caulking in all the holes you created to stop water penetration.

5. Attaching the H-Channel: Panels can be joined together using H-Channel, which seams the two panels together and helps to prevent water leakage. Attach one panel to your frame while leaving about ¼" gap in between that panel and the next one you are attaching. This leaves enough space for you to slide the H-channel into place. Keep the screws approx. 1" from each side of the H-Channel. Do not screw into the H-channel. **Do not use H-channel on a roof, unless it is one continuous H-channel running from side-to-side. No H-channel clips on a roof. If H-channel is difficult to slide on, try spraying the groves of the H-channel and the edges of the panels with a little WD-40, Pam or try rubbing a dry bar of soap on the edges of the panels and tap on the end of the H-channel with a rubber mallet.

Attaching the H-Channel: Panels can be joined together using H-Channel, which seams the two panels together and helps to prevent water leakage. Attach one panel to your frame while leaving about ¼" gap in between that panel and the next one you are attaching. This leaves enough space for you to slide the H-channel into place. Keep the screws approx. 1" from each side of the H-Channel. Do not screw into the H-channel. **Do not use H-channel on a roof, unless it is one continuous H-channel running from side-to-side. No H-channel clips on a roof. If H-channel is difficult to slide on, try spraying the groves of the H-channel and the edges of the panels with a little WD-40, Pam or try rubbing a dry bar of soap on the edges of the panels and tap on the end of the H-channel with a rubber mallet.

6.  Folding the Greenhouse Panels: It's not necessary to cut Solexx corrugated plastic greenhouse paneling when installing over roof peaks or around corners. You can score the greenhouse covering by using a straight edge and a small blunt object such as a Philips screw driver or handle of a butter knife (be careful not to cut the plastic), and then fold the panel along the scored line. Solexx can be scored either in the direction of the flutes or across the flutes.

Folding the Greenhouse Panels: It's not necessary to cut Solexx corrugated plastic greenhouse paneling when installing over roof peaks or around corners. You can score the greenhouse covering by using a straight edge and a small blunt object such as a Philips screw driver or handle of a butter knife (be careful not to cut the plastic), and then fold the panel along the scored line. Solexx can be scored either in the direction of the flutes or across the flutes.

7. Changes in Size: Apply the paneling when the temperature is at the mean (Yearly average) temperature for your area to allow for expansion and contraction.

8. Cleaning Solexx Greenhouse Covering: Wipe down the greenhouse panels with soap and water once a year for maximum light transmission efficiency and to keep your greenhouse looking great!

9. Other Applications: Although corrugated plastic greenhouse panels do not have "building code certification" they have been successfully used for deck coverings, carports, swimming pool covers, porch enclosures, and wood storage. Some have had good results, although we have found that it is not always the most suitable product for these applications.

PLEASE NOTE: Do not use the panels to square your structure. Solexx™ panels and rolls may not be perfectly square.

Share